Limit selection

Filter by:

37 Products

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

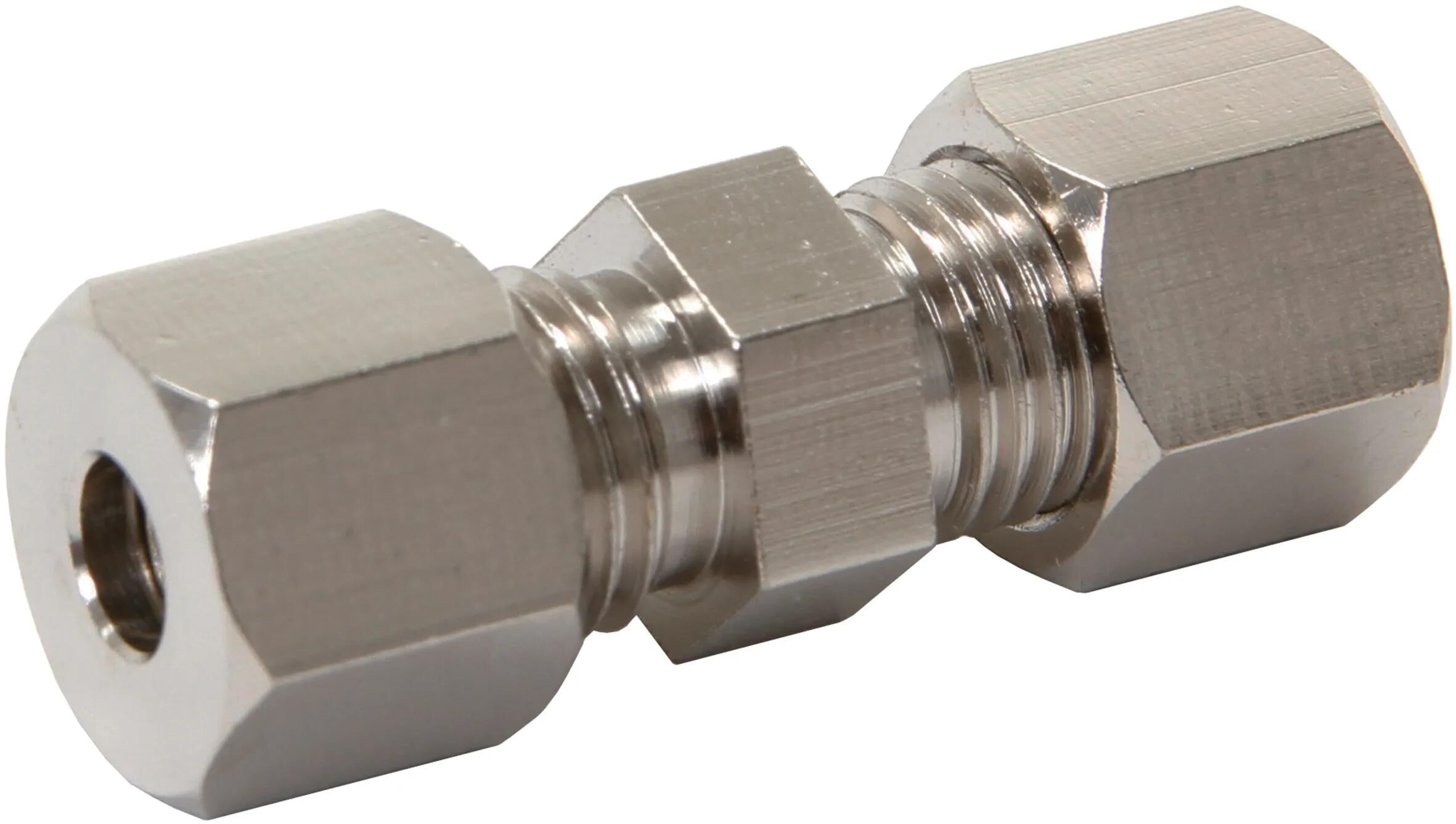

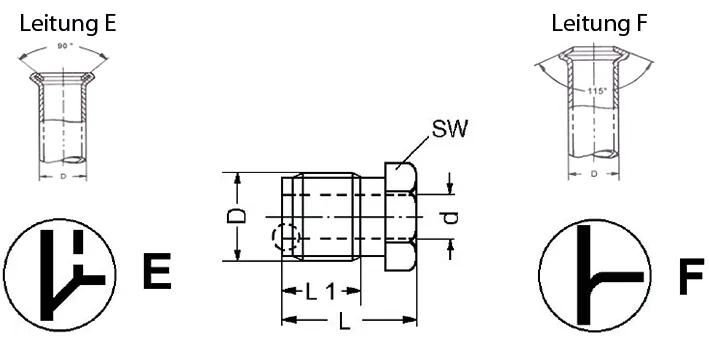

4,75 F, thread M 10 x 1,25 Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

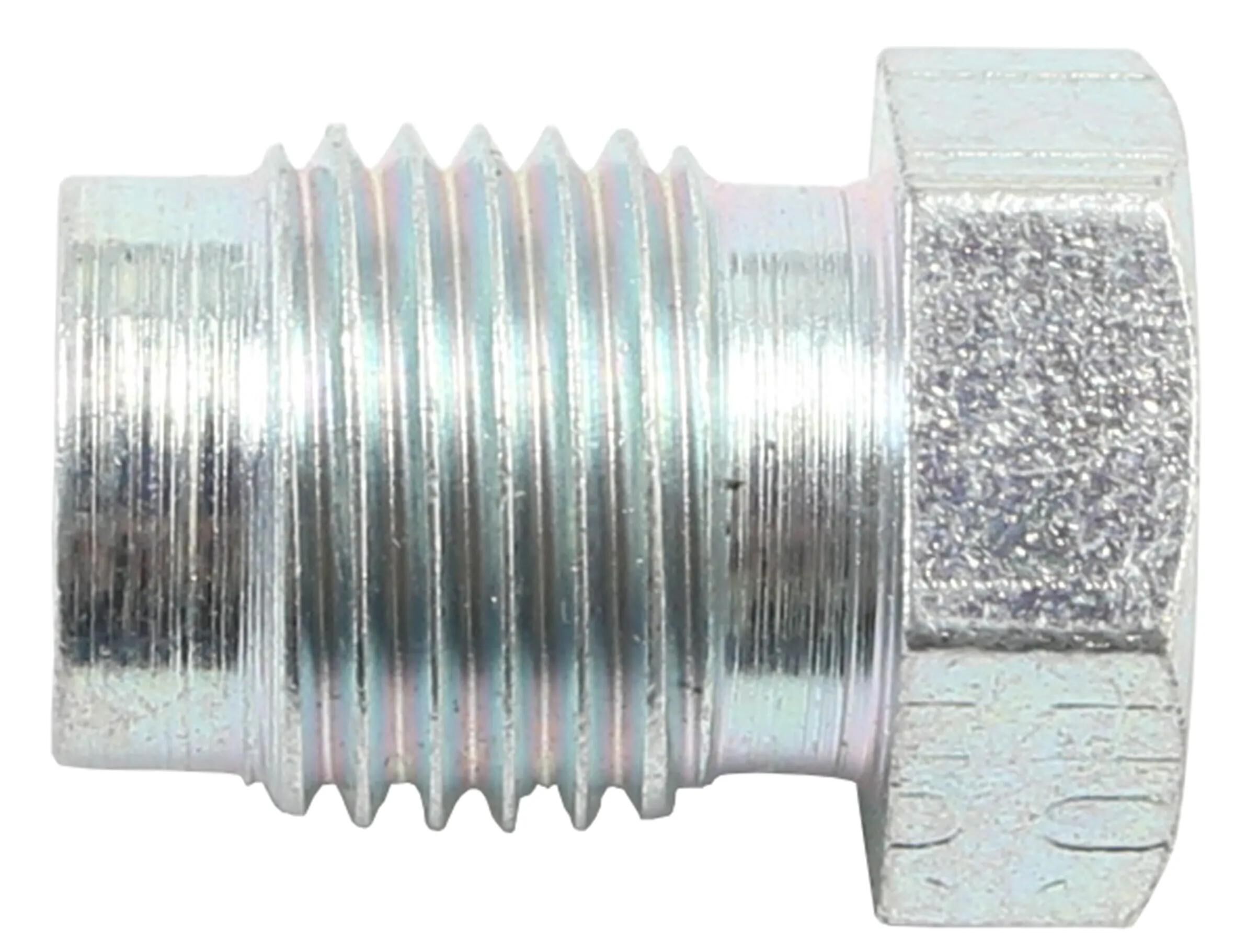

hole Ø: 4,75mm, length over all: 17mm, SW 10 Read more Read less

| PU 100 | ||

hole Ø: 5mm, length over all: 16,7mm, SW10 Read more Read less

| PU 10 | ||

hole Ø: 5mm, length over all: 16,7mm, SW 11 Read more Read less

| PU 10 | ||

bore Ø: 6,2mm, length via all: 18mm, SW12 Read more Read less

| PU 10 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 10 | ||

| PU 1 | ||

PU 1 | |||

| PU 1 | ||

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||

| PU 1 | ||