Limit selection

Filter by:

13 Products

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

"GP3.150WS PLUS" (incl. extensive accessories) Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

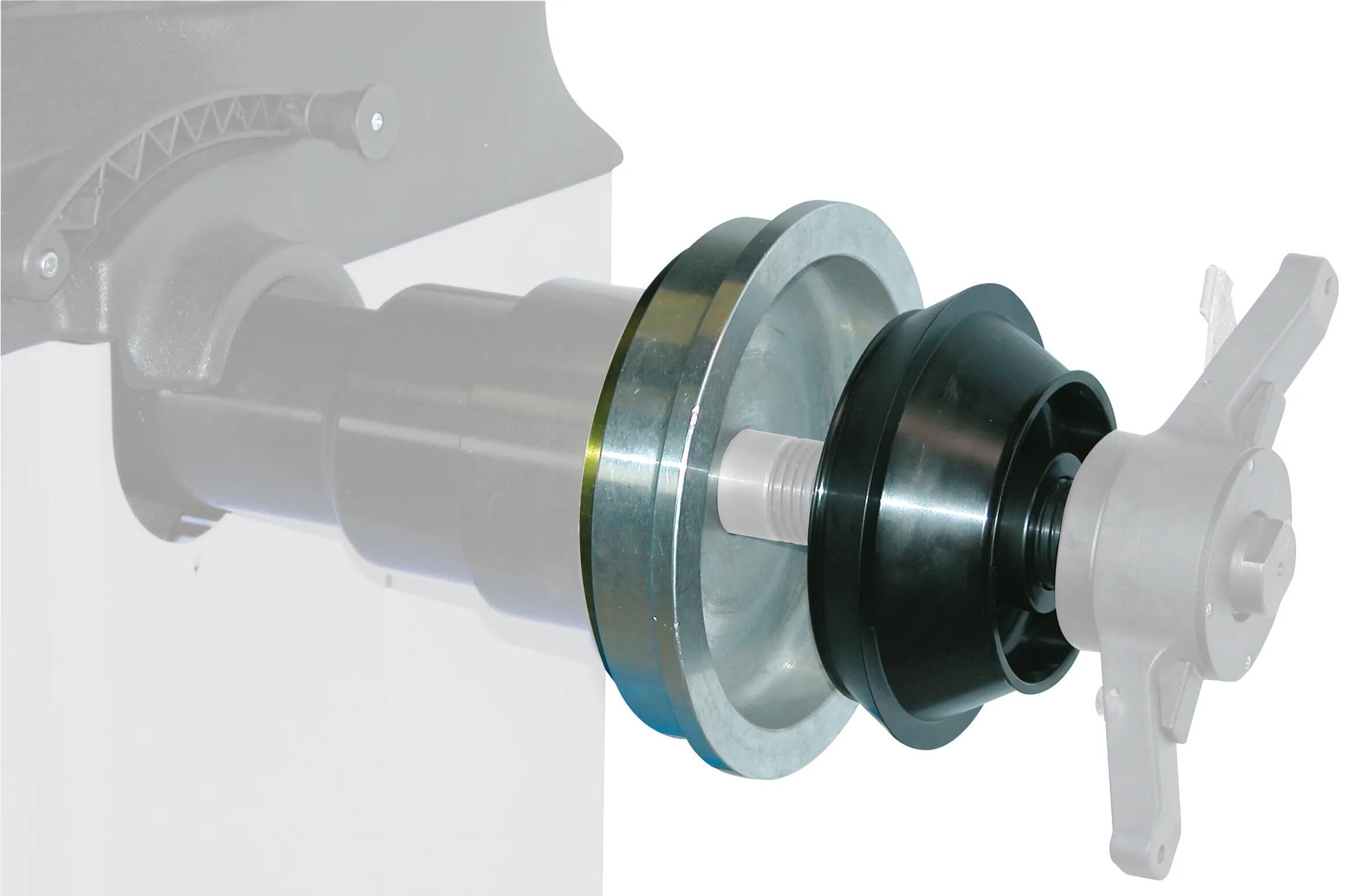

incl. clamping flange AF15 Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

Ø 100 x 138 mm, height: 17 mm Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

"G2.121RFM", standard version Read more Read less

| PU 1 | ||

"G2.121RFM", incl. #GAR301 (automatic rim width sensor) Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

#GAR113, cone and distance piece (D118 + 174) LLKW, for all models Read more Read less

| PU 1 | ||

#GAR213, wheel width catcher, for model G2.124H-GP2.124H and series G3-GP3-G4-GP4-G6-GP6 Read more Read less

| PU 1 | ||

#GAR306, wheel width catcher, for model G3.140R, GP3.140R, G3.140RS, GP3.140RS Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

"G2.124NR", incl. #GAR306 (8.96 53 67/9) Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

plus freight and discharge costs Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

plus freight and discharge costs Read more Read less

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||

Product variants

| Article | Price | ||

|---|---|---|---|

| PU 1 | ||